Better tools and equipment, workshop technology, and communication and training can save time, boost profits, and put a smile on your technician’s face.

Automating parts of a technician’s job to make life easier and free up time for other tasks is a surefire way of improving their environment, while also reducing the potential for job-hopping.

That may be top-of-mind for dealers eyeing their facilities as the technician shortage on the fixed ops side of auto retail remains an overwhelming concern, according to Pete Liebetreu, Vice President of Marketing at Hunter Engineering.

“Recruiting and retaining is really where a lot of their minds are at. They’re looking for solutions that help them in that way,” said Liebetreu in an interview with Canadian auto dealer. “When we talk about what’s important to technicians, it’s the same things that are important to any worker.”

Data from a 2018 Carlisle & Co. Automotive Technician Survey that is being used by Hunter Engineering highlights what those factors are. It is worth noting that not much has changed, post-pandemic, from this survey, which included 35,000 technicians from the United States and Canada with an average age of 40.

The report found that three of the top four areas of dissatisfaction for automotive service technicians is related to equipment. So while 79 per cent of technicians are dissatisfied with their pay plan, 75 per cent are none-too-pleased with diagnostic equipment, followed by workshop technology (73 per cent), and special tools and equipment (70 per cent).

“(Based on the survey, we found that) the ability of technicians to access diagnostic equipment, the workshop technology, and the special tools and equipment — in other words, the things they need to do their jobs — if those things are available to them and they are easy to use and they’re always working…then that’s a great (environment) to work in,” said Liebetreu.

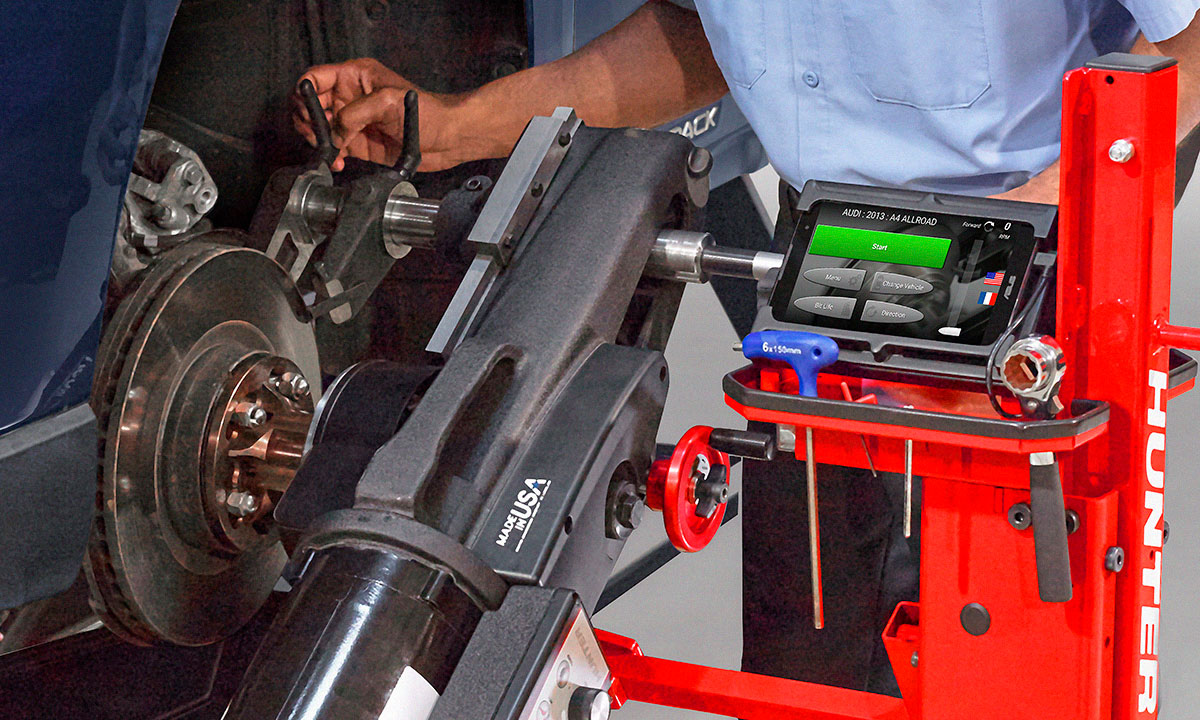

Hunter specializes in these areas. They have products that do automatic wheel alignment, thread-depth measurement, on-site data analysis, vehicle identification that automatically determines OEM specs for most vehicles, and more. Its Revolution Walkaway can do a four-tire changeover 25 per cent faster when in semi-autonomous mode and compared to the manual process.

“That’s both useful for your retention side of things and for the recruiting side,” said Liebetreu. “Time is really important. It’s obviously probably one of the things that we look at the most.”

The right tools

For Reynolds and Reynolds, the right technology can also give technicians the benefit of making more money. And that can make them happier or more satisfied with their job. They just need the right tools to both succeed and save time, according to Lance Alverson, Area Vice President of Sales for Central U.S. and Canada.

He said the company has a fixed operations specialist in Canada that helps them dig into how dealerships are operating to identify where their inefficiencies are.

“One of the things we found out that technicians get frustrated at is identifying work to be sold, and then the advisor not selling it,” said Alverson. “They have to have the tools to give the information to the advisor to sell that properly, which will in turn give them the work to continue and get those cars fixed.”

Doing this, he said, can also improve the level of trust between the technician and advisor, which would be a win-win for both — and also for the dealership and the customer.

Examples of the “right technology” include the ability for the technician to take photos and videos of the vehicle/work being done with their mobile device. That information would then be sent to the advisor, who in turn would review it and email or text the photos/video to the customer for approval. The customer can do this immediately, and electronically.

“I mean, everybody’s mobile today,” said Alverson.

Communication is key

The concept of saving time was also echoed by Elise Parsons, Manager of Account Services at PBS Systems. She highlighted three struggles that dealerships across Canada and the United States are dealing with: staffing, digital disconnect, and communication.

“Time is money. The old adage, right? And time really is a valuable commodity. When you have inefficient communication, you lose so much time going back and forth. So finding ways to leverage really efficient communication is key,” said Parsons.

Dealers know it takes time and money to train new staff, and lack of communication is one of the main frustrations that consumers have when inquiring about the status of their vehicle. For this reason, PBS Systems has an online academy so that whenever there is a lull in the day the technician can log-in.

Global training includes a live person leading sessions on specific topics. They also have knowledge bases that allow technicians to search for specific topics and review a ‘how-to’ with pictures in it.

“We can also leverage technology in terms of making the job require less input. So even if you have an experienced advisor coming from a different manufacturer, they don’t necessarily know your service intervals.”

Parsons said the company has technology that can prompt for recommended services based on the history of the vehicle. Any previously deferred services will prompt. “Even if you don’t know the customer of the car, the system’s doing the work for you to tell you what you need to sell. It’s making it easier to train staff and get them up to speed, and sell where they need to be selling.”

Training and a change in mentality

Training technicians to learn, understand, and use the technology they are being provided with is something KPI Dealer Solutions is focused on.

“Technicians are really in a situation where they have to keep up-to-date,” as the use of technology continues to increase, said Co-founder/Managing Partner Michael Giguère. He recognizes the breadth of technology, from tools to equipment to computer systems, that they must master on top of repairing vehicles.

The challenge today, he said, is keeping technicians up to speed with software, so that they can comfortably do their work in concert with the mechanical and customer service side of their job. Training is especially important because, while some technicians catch on quickly, others do not.

“What we see as the future is a team of expert advisers who will enable technicians to optimize their dealerships, both in terms of fixed operations…and also to allow them to have confidence in the performance of their daily tasks,” said Giguère.

However, even money and training may not be enough if the industry does not change the mentality it has towards technicians — something Giguère hopes to improve. He compares them to doctors, in the sense that they take care of our vehicles. And like doctors, keeping technicians in the long-run will involve valuing them for the work they do.